Custom slab production lines

Kalkman delivers custom solutions on a large scale. Based on the desired quantities, types, sizes, and quality of slabs, our experts advise you on a suitable solution. Our devices for the production, curing, refinements, and packaging of concrete slabs have been continuously developed for decades. This gives you a competitive advantage.

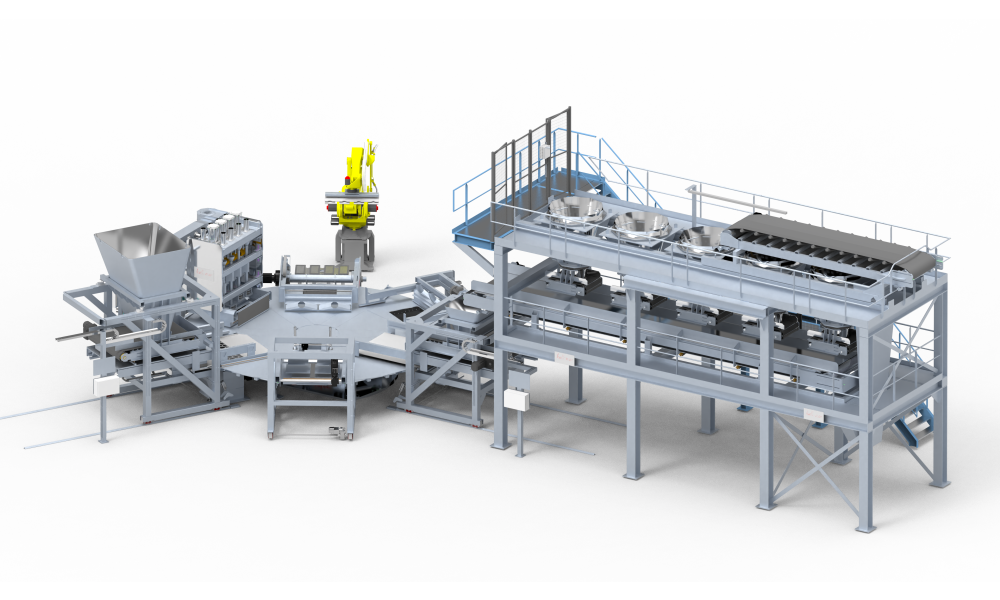

Slab production

Slabs are produced in a machine, consisting of a turntable with molds and various processing stations, fully tailored to your needs. You have the choice between a machine with two or four compaction units.

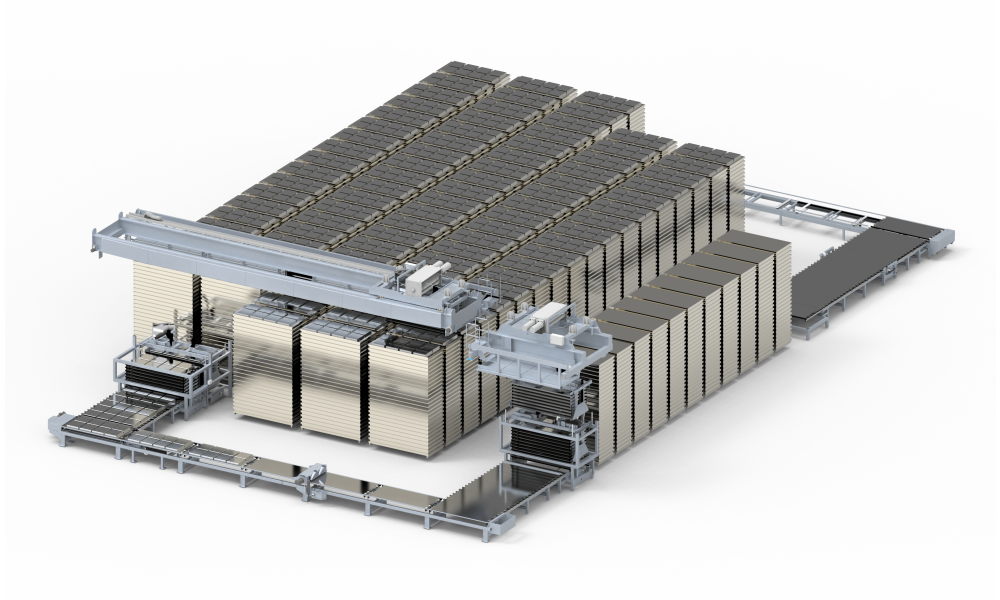

Curing

The freshly produced slabs are placed on trays, where they undergo a curing process in the curing room. Curing can occur naturally or be conditioned, with the humidity level and temperature in the curing room being regulated.

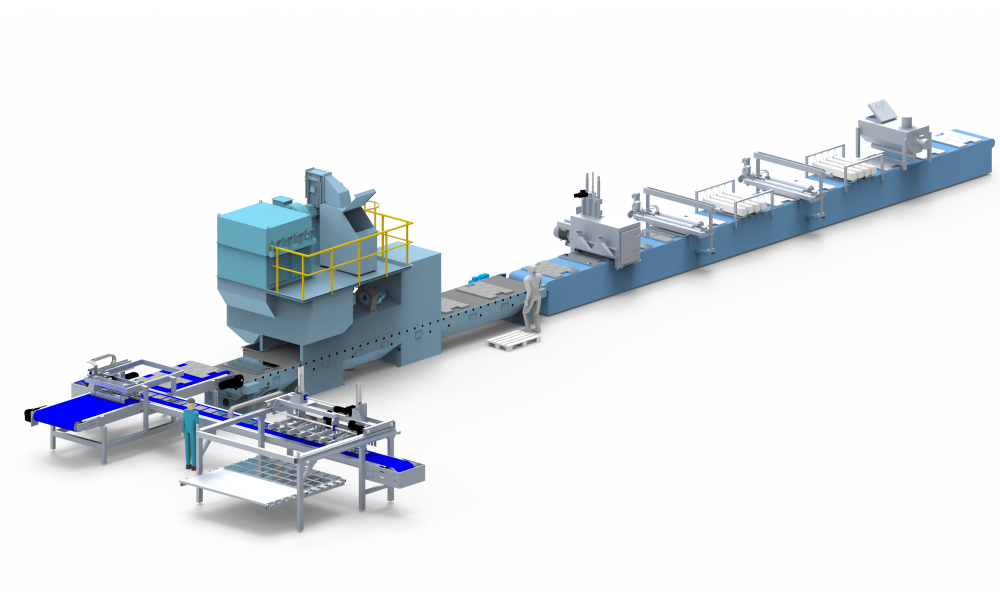

Refinement

After curing, various treatments can be performed on the slabs for enhancing the appearance, protecting, and finishing. Examples of these treatments include shot blasting, brushing, washing, and coating.

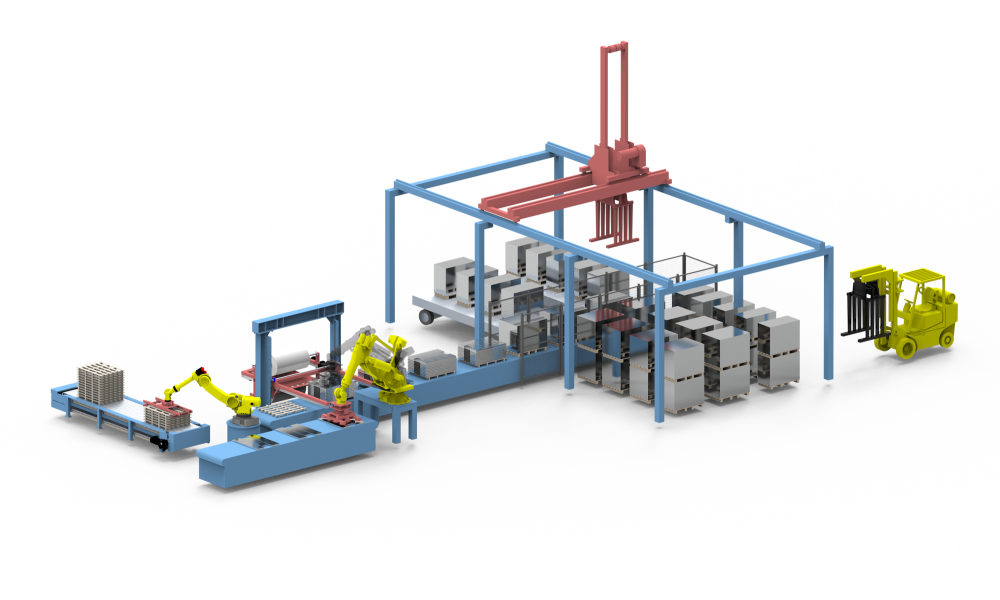

Slab packaging

After the slabs have undergone post-treatment, they are assembled into an efficient, transportable packaging form. With our universal equipment, this can be done either vertically or horizontally, as desired.

Advice for the solution that suits your needs?

.jpg?resolution=850x550&quality=95)