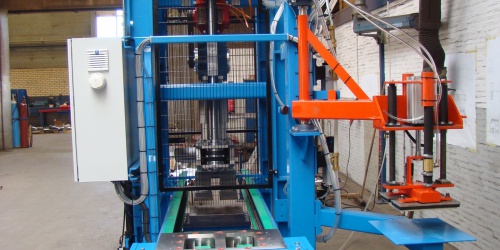

Tamping equipment

Tamping machines

Tamping machines are typically made to carry moulds on a turntable passing various stations with the exposed side of the mould facing downwards. This production machine has the great advantage of a quick throughput process and provides a final product with closed surface and a high degree of compaction compared to vibration systems.

- Moulds are moved along processing stations and have a movable face plate (matrix).

- Products of different thicknesses can be made from one mould;

- Compaction is achieved by tamping the concrete into the mould from above. During compction the face plates are laying on an anvill;

- The product is pushed upwards from the mould and placed on curing pallets;

- The face plate will be cleaned on each production cycle.

- The use of matrixes allows various design opportunities of flat or structured surfaces.

- The tamping technology anables the production of stabilized earth concrete (SEC)

- This technology anables earlier surface treatments

- Sunstantial longer lifetime of moulds due to the use of liners instead of the replacement of the complete mould

- Possibility to use higher percentages of small size aggregates (fly ash)

Product photo 1

Product photo 2

Product photo 3

Product photo 4

Product photo 5

Product photo 6